As industries evolve toward more sustainable and high-performance solutions, ethanol is gaining attention for its versatility and cleaner profile. Yet not all ethanol is created equal. Refined ethanol blends, especially those engineered for purity and consistency, are shaping how manufacturers approach everything from cosmetics and pharmaceuticals to cleaning products and industrial coatings. Cleaner chemistry is no longer optional; it is becoming a strategic advantage worth exploring further. Read more about how these innovations are redefining modern production.

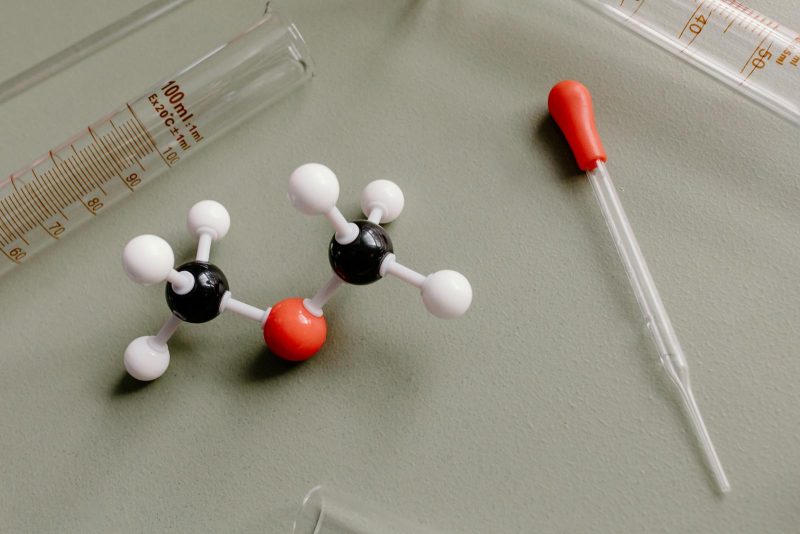

Understanding Refined Ethanol Blends

Ethanol is a key ingredient across numerous industries because of its solvent power, disinfectant properties, and compatibility with other compounds. However, standard grades of ethanol may contain impurities or additives that limit their use in sensitive applications, which is why working with a trusted ethanol distributor is essential to ensure quality and consistency.

Refined ethanol blends are carefully engineered to deliver higher purity and predictable performance. They combine ethanol with precise amounts of denaturants or stabilizers, allowing manufacturers to meet regulatory standards while optimizing efficiency and safety. For example, blends such as CDA 12A are formulated to reduce contaminants and maintain stability, making them ideal for industries that demand strict quality control.

Why Purity Matters

The purity of ethanol directly affects both product quality and safety. In sectors like personal care, pharmaceuticals, and biotechnology, even trace impurities can cause instability or unwanted reactions. A refined ethanol blend helps maintain product consistency and ensures compliance with safety standards.

For cosmetic manufacturers, high-purity ethanol ensures active ingredients perform as intended and the final product remains gentle on the skin. In pharmaceuticals, cleaner blends help preserve formulation efficacy, prevent contamination, and meet regulatory scrutiny. Purity also improves storage stability, reducing product waste and supporting more sustainable production cycles.

The Environmental Advantage

Sustainability plays a central role in the rising demand for refined ethanol blends. Ethanol is renewable when derived from bio-based sources such as corn, sugarcane, or cellulosic biomass. By refining and blending it with precision, producers can achieve both environmental and operational gains.

Cleaner ethanol blends emit fewer volatile organic compounds (VOCs), which contribute to air pollution and health risks. Their lower toxicity and biodegradability make them safer for workers and the environment. Many industries are replacing harsher petrochemical solvents with refined ethanol because it aligns with green manufacturing goals without compromising performance.

In addition, the refining process itself is evolving. Modern facilities are adopting energy-efficient distillation methods and circular recovery systems that recycle waste streams. These innovations make refined ethanol not only cleaner in use but also cleaner in production.

Industrial Applications Across Sectors

Refined ethanol blends have proven helpful in a wide range of industries, each benefiting from their balance of performance, safety, and sustainability.

Personal Care and Cosmetics

In cosmetics, ethanol acts as a solvent, preservative, and stabilizer. High-purity blends ensure that fragrances, essential oils, and active compounds remain stable without introducing irritants or residue. The demand for “clean beauty” products has intensified the shift toward ethanol blends that meet both consumer and regulatory expectations for purity.

Pharmaceuticals and Healthcare

Hospitals, laboratories, and pharmaceutical manufacturers rely on ethanol for sterilization, compounding, and formulation. Refined blends deliver reliable antimicrobial activity while minimizing risks associated with impurities or inconsistent concentrations.

Cleaning and Sanitizing Solutions

The global rise in hygiene awareness has driven higher demand for alcohol-based sanitizers and surface cleaners. Refined ethanol blends allow manufacturers to produce products that are both effective and compliant with international safety standards.

Industrial Manufacturing

Blends of ethanol are also becoming more popular in the production of electronics, coatings, and inks. They are perfect for applications needing accuracy and cleanliness because of their high volatility and low residue. Refined ethanol improves the quality of the final product by leaving surfaces free of impurities due to its clean evaporation.

Efficiency Through Refinement

One of the strongest arguments for refined ethanol blends is their ability to enhance efficiency across supply chains. When ethanol quality is consistent, manufacturers experience fewer production delays and less waste from rejected batches. Higher purity levels also mean that less solvent is needed to achieve the same performance, which reduces costs over time.

Refined blends are easier to handle and store because their controlled composition minimizes chemical reactions and degradation. This leads to longer shelf life, lower maintenance, and greater predictability in industrial processes.

In short, refining ethanol is not just about making it cleaner; it is about making production smarter.

Market Drivers and Industry Outlook

Consumer demand, regulatory pressure, and technological advancements all contribute to the movement toward cleaner ethanol blends. While brands strive to meet sustainability goals, governments continue to tighten regulations on solvent emissions and chemical waste.

Expectations have also changed as a result of increased public awareness of the environmental and human health impacts. Businesses must demonstrate not only that their goods are effective but also that they are produced ethically. Blends of refined ethanol support this change by providing a concrete means of proving ethical and scientific responsibility.

The demand for ethanol is expected to continue rising, according to market analysts, particularly in high-purity applications. Ethanol’s versatility is likely to grow into even more specialized fields as refining technologies advance.

Final Thoughts

Refined ethanol blends represent the intersection of performance, safety, and sustainability. As businesses aim for cleaner chemistry and more innovative industry practices, the importance of ingredient quality has never been greater. From beauty products to pharmaceuticals and industrial processes, ethanol’s evolution reflects a broader movement toward responsible innovation. The future of clean chemistry begins not in marketing, but in the molecules themselves, and refined ethanol is leading the way. Read more about how this shift is shaping safer, more sustainable industries.

![Is Kodi Legal? Is Kodi Safe? [You Must Know This]](https://www.meritline.com/wp-content/uploads/2019/04/feature-100x70.jpg)